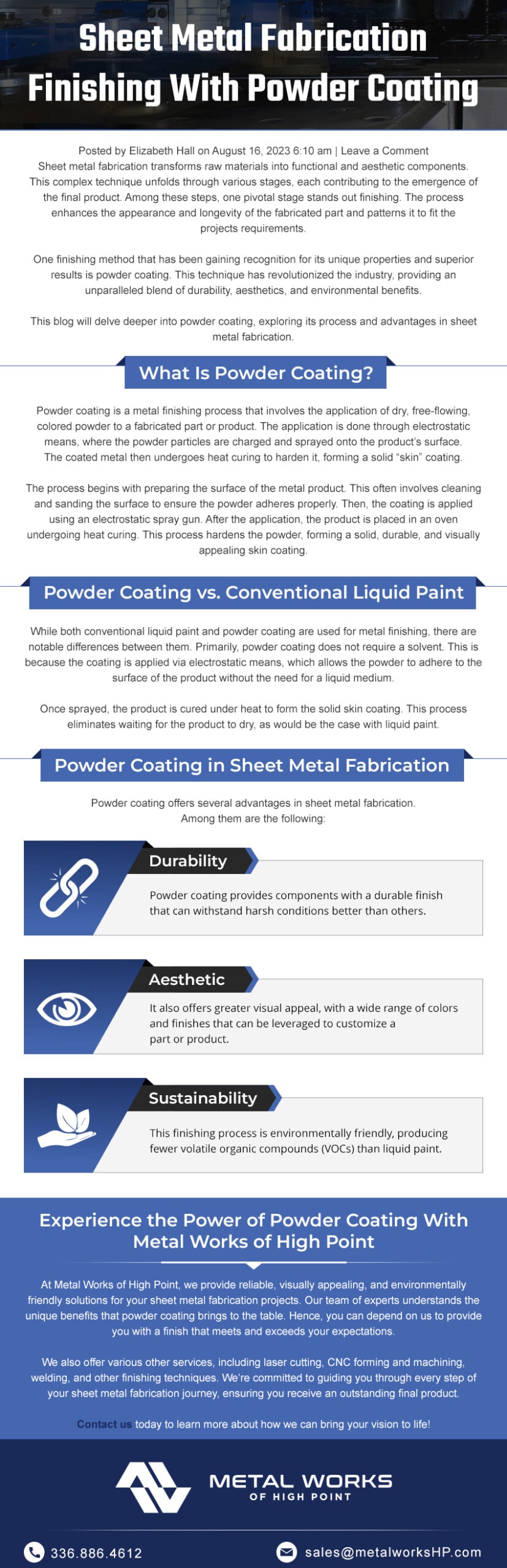

Sheet metal fabrication transforms raw materials into functional and aesthetic components. This complex technique unfolds through various stages, each contributing to the emergence of the final product. Among these steps, one pivotal stage stands out finishing. The process enhances the appearance and longevity of the fabricated part and patterns it to fit the projects requirements.

One finishing method that has been gaining recognition for its unique properties and superior results is powder coating. This technique has revolutionized the industry, providing an unparalleled blend of durability, aesthetics, and environmental benefits.

This blog will delve deeper into powder coating, exploring its process and advantages in sheet metal fabrication.

What Is Powder Coating?

Powder coating is a metal finishing process that involves the application of dry, free-flowing, colored powder to a fabricated part or product. The application is done through electrostatic means, where the powder particles are charged and sprayed onto the product’s surface. The coated metal then undergoes heat curing to harden it, forming a solid “skin” coating.

The process begins with preparing the surface of the metal product. This often involves cleaning and sanding the surface to ensure the powder adheres properly. Then, the coating is applied using an electrostatic spray gun. After the application, the product is placed in an oven undergoing heat curing. This process hardens the powder, forming a solid, durable, and visually appealing skin coating.

Powder Coating vs. Conventional Liquid Paint

While both conventional liquid paint and powder coating are used for metal finishing, there are notable differences between them. Primarily, powder coating does not require a solvent. This is because the coating is applied via electrostatic means, which allows the powder to adhere to the surface of the product without the need for a liquid medium.

Once sprayed, the product is cured under heat to form the solid skin coating. This process eliminates waiting for the product to dry, as would be the case with liquid paint.

Powder Coating in Sheet Metal Fabrication

Powder coating offers several advantages in sheet metal fabrication. Among them are the following:

- Durability: Powder coating provides components with a durable finish that can withstand harsh conditions better than others.

- Aesthetic: It also offers greater visual appeal, with a wide range of colors and finishes that can be leveraged to customize a part or product.

- Sustainability: This finishing process is environmentally friendly, producing fewer volatile organic compounds (VOCs) than liquid paint.

Experience the Power of Powder Coating With Metal Works of High Point

At Metal Works of High Point, we provide reliable, visually appealing, and environmentally friendly solutions for your sheet metal fabrication projects. Our team of experts understands the unique benefits that powder coating brings to the table. Hence, you can depend on us to provide you with a finish that meets and exceeds your expectations.

We also offer various other services, including laser cutting, CNC forming and machining, welding, and other finishing techniques. We’re committed to guiding you through every step of your sheet metal fabrication journey, ensuring you receive an outstanding final product.

Contact us today to learn more about how we can bring your vision to life!