Computer numerical control (CNC) bending and panel bending help fabricate a variety of metal components. When determining whether this fabrication method is ideal for a particular product, it’s important to understand what panel bending is and how it works. At Metal Works of High Point, we offer a range of CNC metal forming services for our clients’ unique specifications. Learn more about CNC panel bending here.

Computer numerical control (CNC) bending and panel bending help fabricate a variety of metal components. When determining whether this fabrication method is ideal for a particular product, it’s important to understand what panel bending is and how it works. At Metal Works of High Point, we offer a range of CNC metal forming services for our clients’ unique specifications. Learn more about CNC panel bending here.

What Is Panel Bending?

Panel bending is one of many methods used for sheet metal fabrication. Automated and semi-automated processes such as CNC panel bending, which use CAD and CAM drawings, produce metal pieces with tight tolerances. Panel bending systems rely on specially designed panel bender machines. The process differs from regular bending, which usually takes place on press brakes or progressive dies.

Depending on the application’s specific needs, the CNC bending process may involve different types of panel bends, including:

- Sharp — In sharp bends, the radius is smaller than the minimum bend radius, while the center of the radius is creased to produce a sharp bend.

- Radius — A custom bend radius depends on the customer’s unique specifications.

- Step bending — A step bend comprises a large bend radius divided into several smaller bends, which form a slightly larger radius.

- Hemming — These bends consist of sheet metal edges bent to 180°, creating a hem at the edge.

Advantages of Panel Bending

Panel bending offers numerous benefits that make it a suitable fabrication method for many applications. The process works particularly well for larger components, as it’s generally more economical and can meet tighter tolerances than other methods. Additionally, panel bending processes only require a single operator. The alternative would be a two-person press brake operation that’s more expensive, increases the likelihood of errors, and doesn’t allow for tight tolerances.

Press Brakes vs. Panel Benders

Press brakes and panel benders have some key differences to keep in mind. While press brakes use a punch and die set to shape materials, CNC panel benders use part manipulators along with bladed bending units. Understanding the differences between press brakes and panel benders can help you determine which to use for a given application.

The panel bending process involves the following steps:

- The manipulator fixes the workpiece in place in front of the panel bender.

- The panel bender’s blades bend the workpiece by applying force either upward or downward.

- The operator turns the workpiece as needed to bend different sides.

- Once bending is complete, the operator removes the finished material from the panel bender.

Dimensions and Design Considerations for Panel Bending

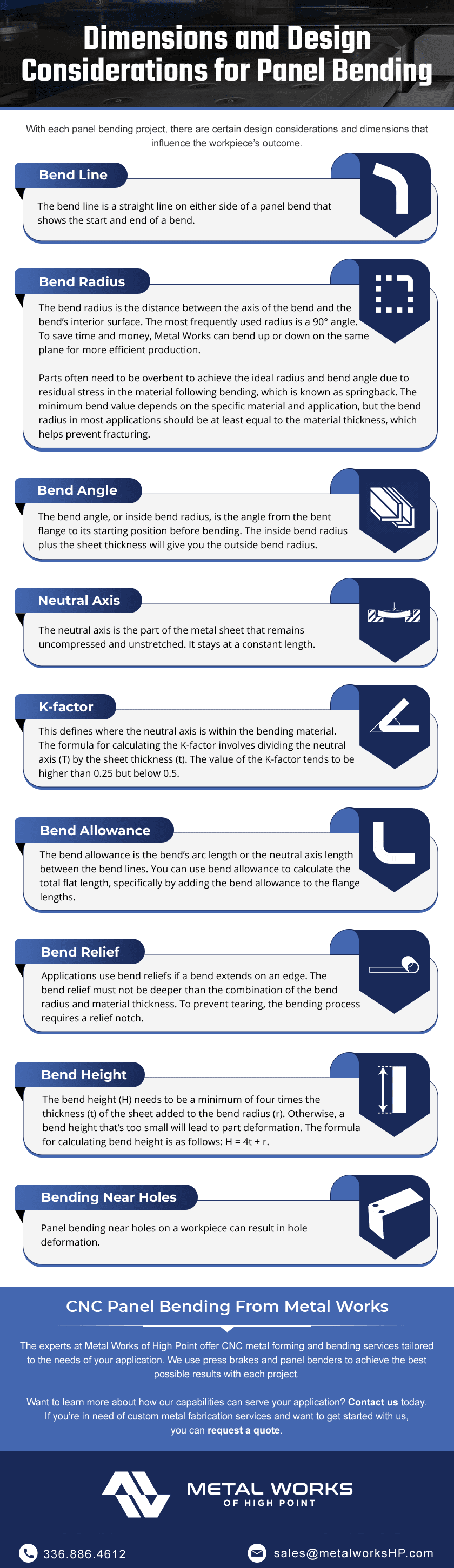

With each panel bending project, there are certain design considerations and dimensions that influence the workpiece’s outcome.

Bend Line

The bend line is a straight line on either side of a panel bend that shows the start and end of a bend.

Bend Radius

The bend radius is the distance between the axis of the bend and the bend’s interior surface. The most frequently used radius is a 90° angle. To save time and money, Metal Works can bend up or down on the same plane for more efficient production.

Parts often need to be overbent to achieve the ideal radius and bend angle due to residual stress in the material following bending, which is known as springback. The minimum bend value depends on the specific material and application, but the bend radius in most applications should be at least equal to the material thickness, which helps prevent fracturing.

Bend Angle

The bend angle, or inside bend radius, is the angle from the bent flange to its starting position before bending. The inside bend radius plus the sheet thickness will give you the outside bend radius.

Neutral Axis

The neutral axis is the part of the metal sheet that remains uncompressed and unstretched. It stays at a constant length.

K-factor

This defines where the neutral axis is within the bending material. The formula for calculating the K-factor involves dividing the neutral axis (T) by the sheet thickness (t). The value of the K-factor tends to be higher than 0.25 but below 0.5.

Bend Allowance

The bend allowance is the bend’s arc length or the neutral axis length between the bend lines. You can use bend allowance to calculate the total flat length, specifically by adding the bend allowance to the flange lengths.

Bend Relief

Applications use bend reliefs if a bend extends on an edge. The bend relief must not be deeper than the combination of the bend radius and material thickness. To prevent tearing, the bending process requires a relief notch.

Bend Height

The bend height (H) needs to be a minimum of four times the thickness (t) of the sheet added to the bend radius (r). Otherwise, a bend height that’s too small will lead to part deformation. The formula for calculating bend height is as follows: H = 4t + r.

Bending Near Holes

Panel bending near holes on a workpiece can result in hole deformation.

CNC Panel Bending From Metal Works

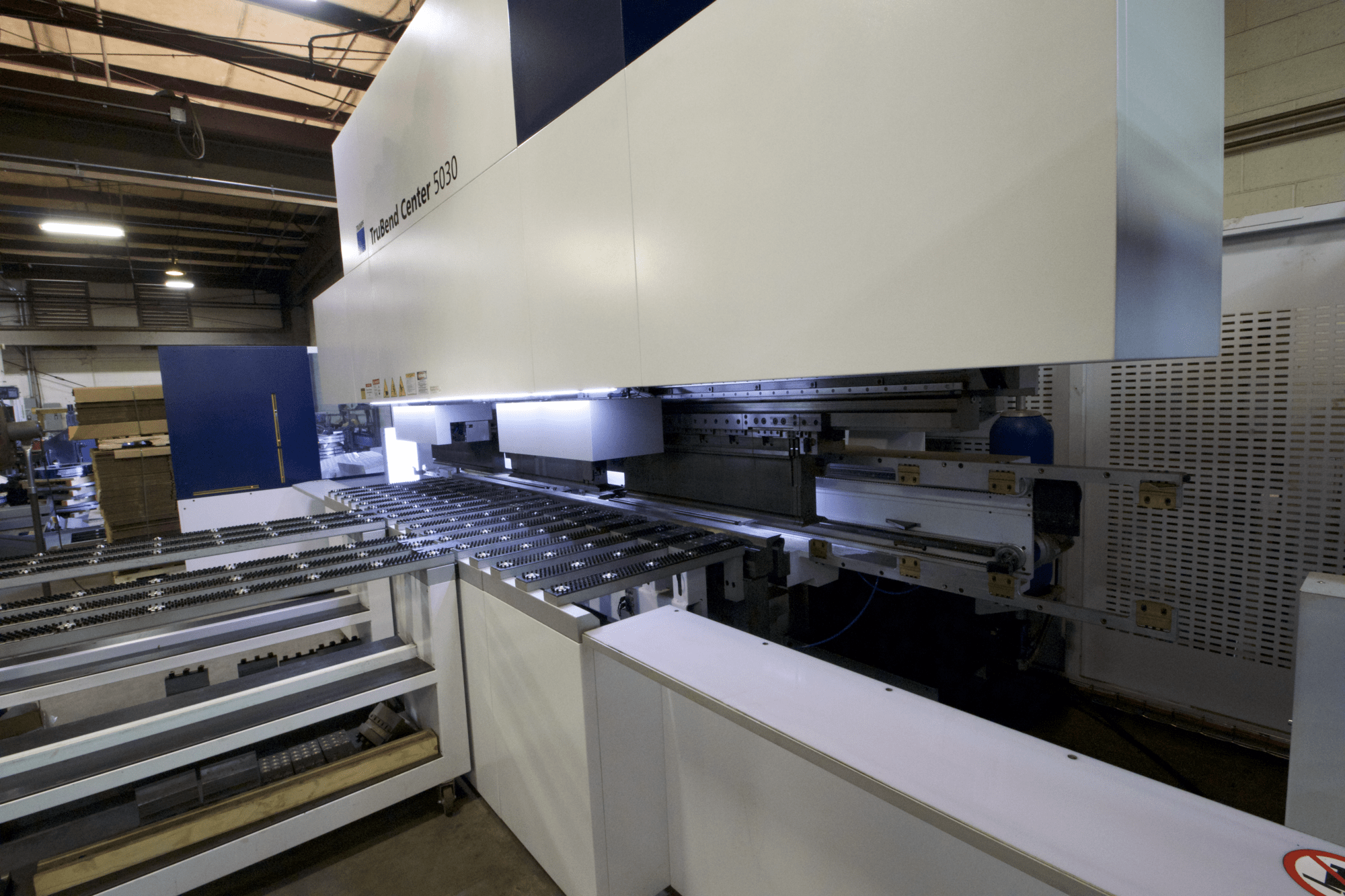

The experts at Metal Works of High Point offer CNC metal forming and bending services tailored to the needs of your application. We use press brakes and panel benders to achieve the best possible results with each project.

We have experience with a wide range of industries, including material handling, appliances, telecommunications, transportation, contract furniture, construction and aerial lifts, and power generation. You can learn more about our past work through our case studies.

Since our establishment in 1992, Metal Works of High Point has developed into a leading provider of turnkey contract metal fabrication solutions for a diverse portfolio of clients. We work to give our clients high-quality custom components with an emphasis on top-tier customer service, respect, and honesty behind each project. Whenever our clients work with us, they benefit from personalized and consistently responsive service, along with state-of-the-art technology and high skill levels.

In addition to CNC bending and metal forming, we offer a host of other solutions, including laser cutting, welding, and finishing. We adhere to our five core values of honesty and integrity, dependability, respect, innovation, and commitment to excellence. In giving our clients the best, we aim to improve delivery times and cut down on costs while maintaining the highest level of quality. To ensure this, we invest in the most advanced technology available and employee training.

Want to learn more about how our capabilities can serve your application? Contact us today. If you’re in need of custom metal fabrication services and want to get started with us, you can request a quote.