Machining involves processes that remove excess material from a workpiece to make it match a design plan. Precision CNC machining produces results with higher accuracy within tight tolerances based on complex designs. CNC machines can handle machining tasks independently, thereby reducing the risk of human error.

At Metal Works of High Point, we specialize in CNC precision machining for creating custom metal components. Our facility includes CNC machines for milling, lathing, and tooling high volume orders. We also provide valuable in-house services for complete product creation and management.

The Machining Process

The CNC machining process has four basic steps, including:

- Designing the CAD Model. Product engineers or design specialists create a CAD design model or rendering of the desired part. The design software takes into account the limitations of CNC tools and processes to ensure the design is possible to achieve while still fulfilling the project’s primary objectives. Designers can test the product through virtual simulations and assess different thicknesses, materials, and part complexities before finalizing their design.

- Converting the CAD File to a CNC Program. Once the CAD file is complete, it is run through a program, typically CAM software, to generate a digital programming code that the CNC machine follows to produce the part. The most common programming language is G-code, which dictates when, where, and how the CNC equipment moves. M-code designates the CNC machine’s miscellaneous functions, such as the removal of the machine cover.

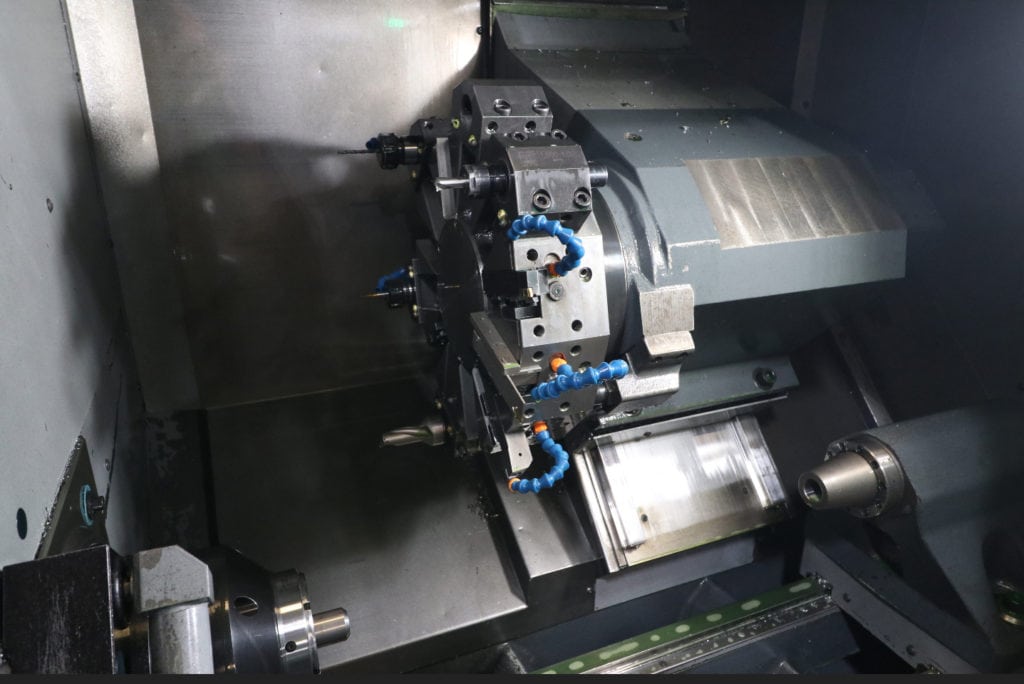

- Preparing the CNC Machine. Operators position the workpiece into the machine using the appropriate workholding device and attach the required tooling, such as end mills and drill bits, to the correct machine components. Once this is done, the operator can run the CNC program.

- Executing the Machining Operation and Part Production. Once setup is complete, the CNC equipment begins to follow the program’s instructions in a repetitive, step-by-step manner to execute the precise removal of material until the workpiece matches the original design within set tolerances. Once complete, the workpiece moves onto the finishing stage.

Advantages of CNC Fabrication

CNC fabrication is a fast, precise, and repeatable process that offers many advantages including:

- Fully Automated. CNC processes are run by programming software, making them fully automated. These increasingly complex systems can manage high quality machining tasks, including positioning the workpiece, inspecting the work, and moving the piece to the next production stage.

- Cost-effective. CNC fabrication is more efficient and requires fewer human workers than traditional manufacturing processes. This lowers the cost of production per unit for both long and short production runs.

- High Quality Production. CNC machining equipment can produce high quality pieces with smoother finishes and high dimensional tolerances.

- Versatility and Flexibility. CNC equipment has multiple tooling functions capable of creating complex parts with a wide variety of metals.

Applications

CNC machining is popular in the following industries for creating a wide variety of parts, both custom and standard:

- Commercial. Precision machined parts such as equipment components and tools are easier to produce at high volumes with CNC machining.

- Furniture and Appliances. CNC machines are used to create furniture and appliance components such as fasteners and hardware.

- Material Handling. Material handling equipment and related robotics are increasingly complex systems that need precision components to perform detailed, intricate motions.

- Transportation. CNC machining is used to create intricate vehicle parts using metals and thermoplastics.

Custom CNC Metal Products From Metal Works

Metal Works of High Point is a leading provider of high quality precision machining services. Along with our core machining and manufacturing capabilities, we also provide in-house CNC forming, laser cutting, and welding. Contact us today to learn more about our services, or request a quote for pricing details on your next project.