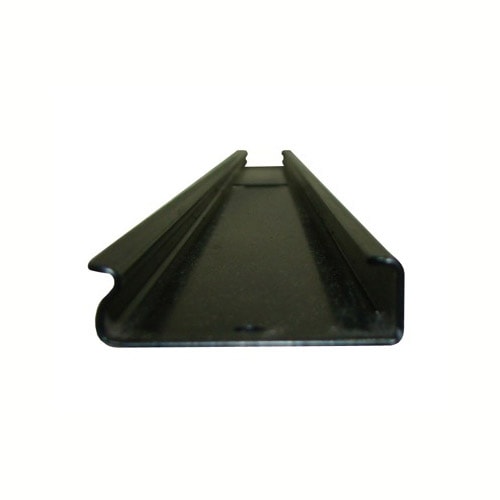

In addition to custom metal fabrication, at Metal Works of High Point, Inc., we are able to use advanced CAD modeling systems to verify the manufacturability of customers’ designs as well as fine tune fabrication processes to ensure parts meet all customer specifications. The project highlighted here includes the fabrication and powder coating of a C-clip used by a customer in the material handling industry. The C-clip is constructed of 18 gauge galvanized cold rolled steel and measures 44.38″ in length, 1.75″ in width, and 0.5″ in height. We manufacture this clip using a combination of precision laser cutting and CNC press brake forming processes. When provided with the specifications for this part, our engineers were challenged with developing these processes to meet the customers’ tight dimensional tolerance specifications of ±0.010″. The kerf of the laser and the strain of the metal after bending all posed challenges in achieving the required tolerances.

To meet these challenges, the part was drawn in 3D modeling software, allowing us to simulate these production processes and compensate for dimensional changes in the metal blank by accurately programming the CAM software which controls the CNC equipment. Using this method, we were able to hold all dimensional tolerances as specified by the customer. After fabrication, the C-clips are powdered to provide a matte black finish. We produce approximately 1,000 C-clip assemblies per month with a lead time of two weeks per order. For additional details regarding this custom metal fabrication project, see the table below, or contact us directly.