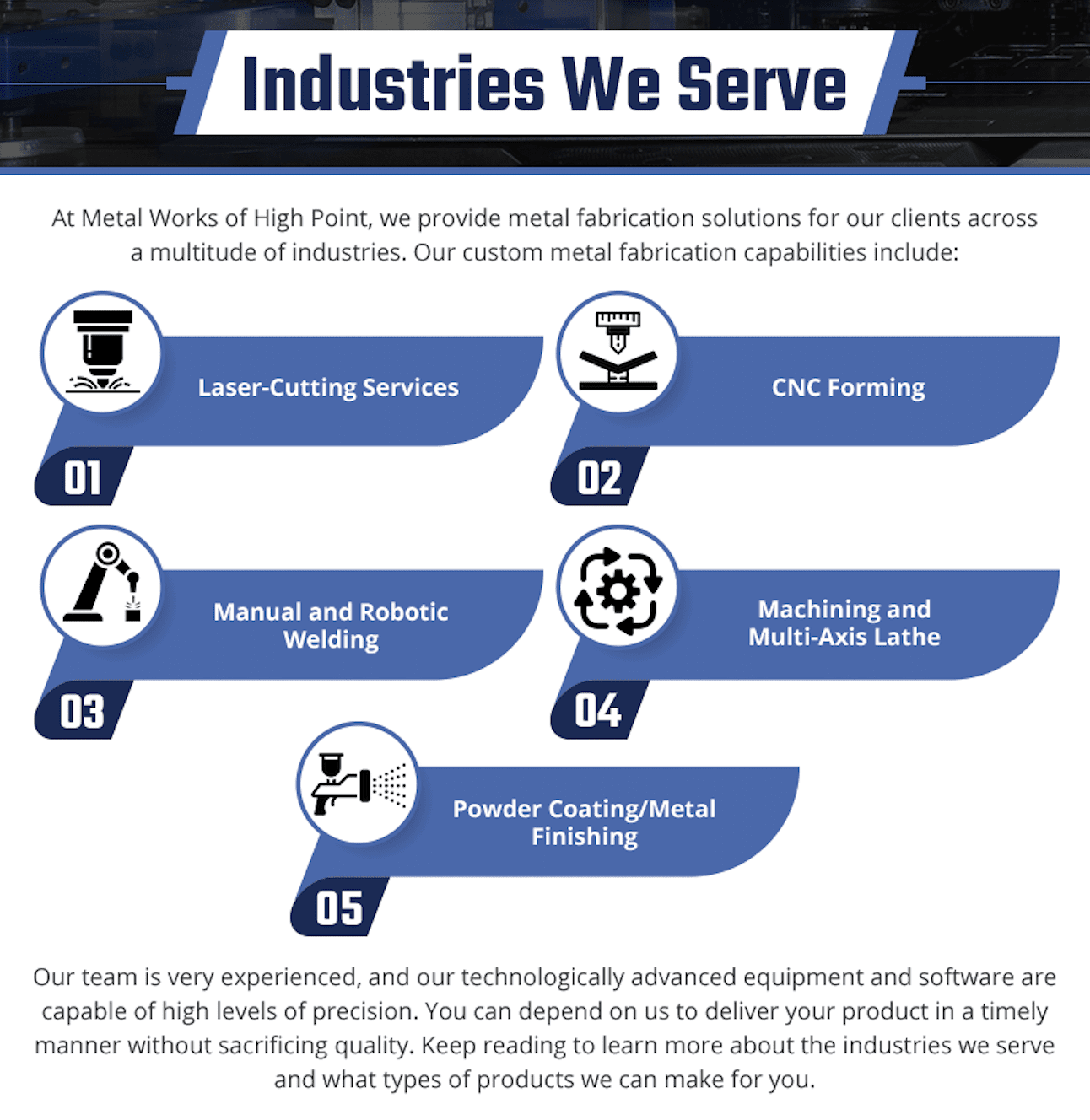

At Metal Works of High Point, we provide metal fabrication solutions for our clients across a multitude of industries. Our custom metal fabrication capabilities include:

At Metal Works of High Point, we provide metal fabrication solutions for our clients across a multitude of industries. Our custom metal fabrication capabilities include:

- Laser-Cutting Services

- CNC Forming

- Manual and Robotic Welding

- Machining and Multi-Axis Lathe

- Powder Coating/Metal Finishing

Our team is very experienced, and our technologically advanced equipment and software are capable of high levels of precision. You can depend on us to deliver your product in a timely manner without sacrificing quality. Keep reading to learn more about the industries we serve and what types of products we can make for you.

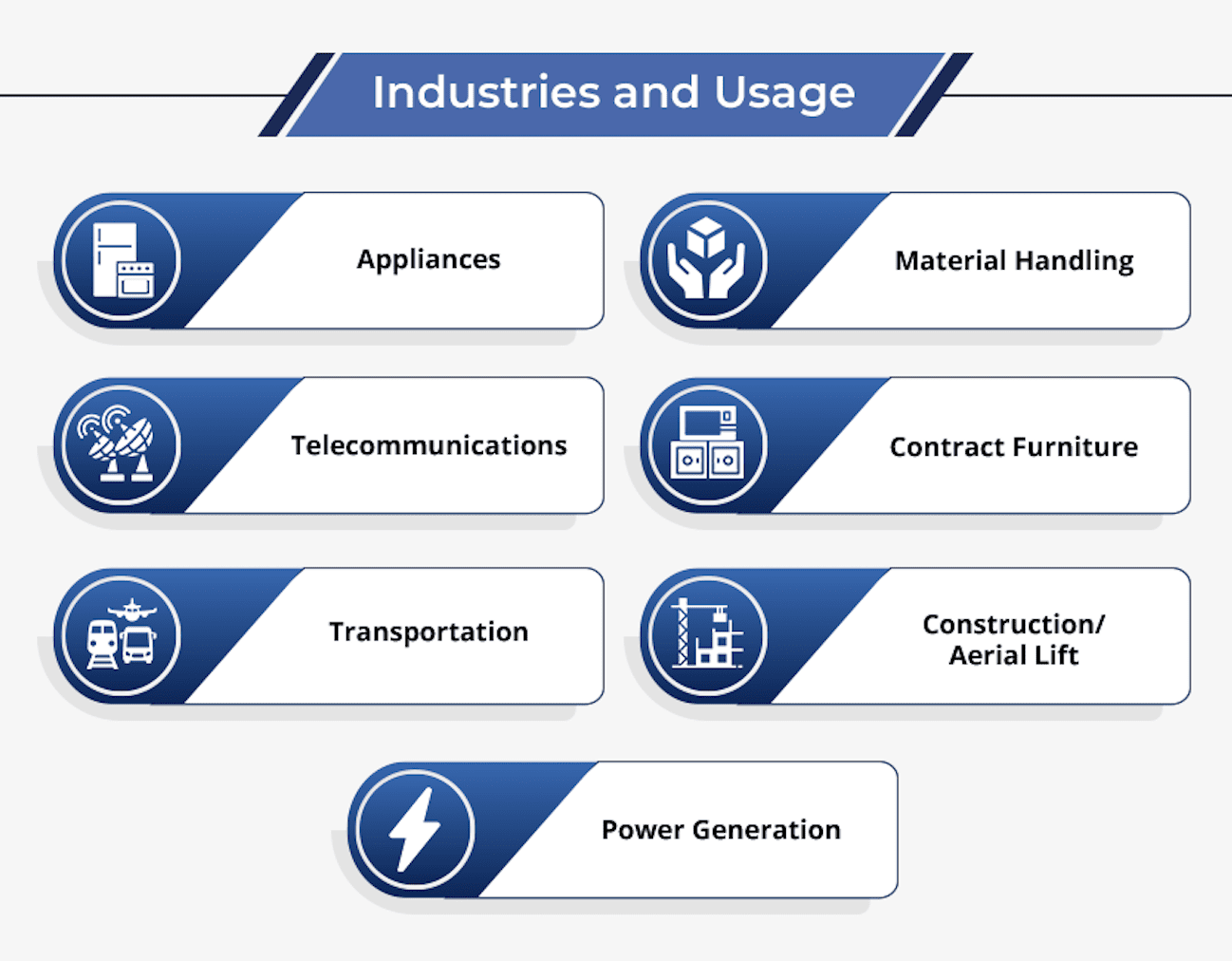

Industries and Usage

Appliances

Appliances

For the appliance industry, we use our CNC-machining capabilities to create fasteners and other hardware. We employ our state-of-the-art laser cutters to drill and cut the metal and plastic parts that form the outer casings of washing machines, refrigerators, air conditioners, and other appliances. Some products undergo our powder-coating process, which applies a durable finish to the product, protecting it from corrosion. Examples of appliances that use powder coating include refrigerators, washer tops and lids, dryer drums, dishwashers, microwave oven cavities, freezer cabinets, and external air conditioning units.

We offer personalized solutions to every one of our valued customers. Check out the custom-fabricated support chassis we manufactured for one of our customers in the appliance industry.

Material Handling

Robots and other equipment in the material handling industry require precision components to perform detailed, intricate motions. We manufacture those components using our CNC machine. We create a wide range of standard and custom parts for this industry, including metal sheets, plates, coils, and bars. From a simple L-shaped bracket to a highly complex tubular frame, our team makes many pieces that fit into larger assemblies used in the material handling industry. This C-clip is a good example of a specific challenge we solved using advanced CAD modeling systems, precision laser cutting, and CNC press brake-forming processes.

Telecommunications

Telecommunication companies rely on us for high quality parts and devices, such as access panel frames, heat sinks, shielding equipment, microwave tower components, antennas, and amplifier housings. Our components guard against the problems seen with poorer quality parts, such as failed equipment, which can result in call interruptions, bad video transmission quality, or worse.

We use CNC machining to ensure accurate manufacturing. Our advanced technology helps us design and produce the complex special parts that this industry needs. This chassis is particularly complex – designed to secure several components within an enclosure. We used the latest 3D modeling and CAM programming technologies to fabricate the chassis to meet the needs of one of our telecommunications customers.

Contract Furniture

Our team uses CNC forming and welding to make bed frames, sofa frames, tables, chairs, and cabinets. Fasteners and hardware are created with CNC machining. Take a look at this wall bracket we manufactured. It is used in stadium seating and other office and institutional furniture applications.

We also provide metal-finishing services to the contract furniture industry. For example, we can prep metal surfaces, or add protective coatings on outdoor patio furniture to protect against corrosion, moisture, and harmful UV rays.

Transportation

Because we offer the flexibility of creating custom metal parts, we can fabricate unique items for the transportation industry. Trains and ships require customized, intricate parts in order to function properly. Consider a railway. We can produce large numbers of railroad bolts, fasteners, and spikes that are specially designed and formulated for the railway. We can also manufacture the rails themselves. In the automotive industry, we use CNC machining to create intricate parts for vehicles using metals and thermoplastics. We designed and manufactured this matte black powder-coated drip pan for one of our customers in the transportation industry.

Construction/Aerial Lift

Our metal fabrication capabilities allow us to produce components for a variety of aerial lifts, including aerial work platforms, scissor lifts, and vertical man lifts. Our team knows the aerial lift industry well, and we are able to provide custom solutions in a timely manner.

Power Generation

Power generation equipment needs to be very durable and long-lasting because it performs under harsh conditions for years and years. We use CNC milling to produce components for wind turbines, nuclear plants, solar energy providers, oil companies, and more. Some of the products we manufacture for green energy and oil and gas industries include:

- Wind turbine blades

- Wind turbine bearings

- Gears, gearbox housings, and rotors

- Solar panel frames and rails

- Hydroelectric turbine impellers

- Gears, support structures, valves, and pump handles for offshore oil and gas rigs

- Frames that support powerful engines

Contact Us for the Custom Metal Parts You Need in Your Industry

We are leaders in the metal parts fabrication industry, and we are eager to serve you in your industry! Give us a call, or request a quote to find out how we can meet your metal parts needs.