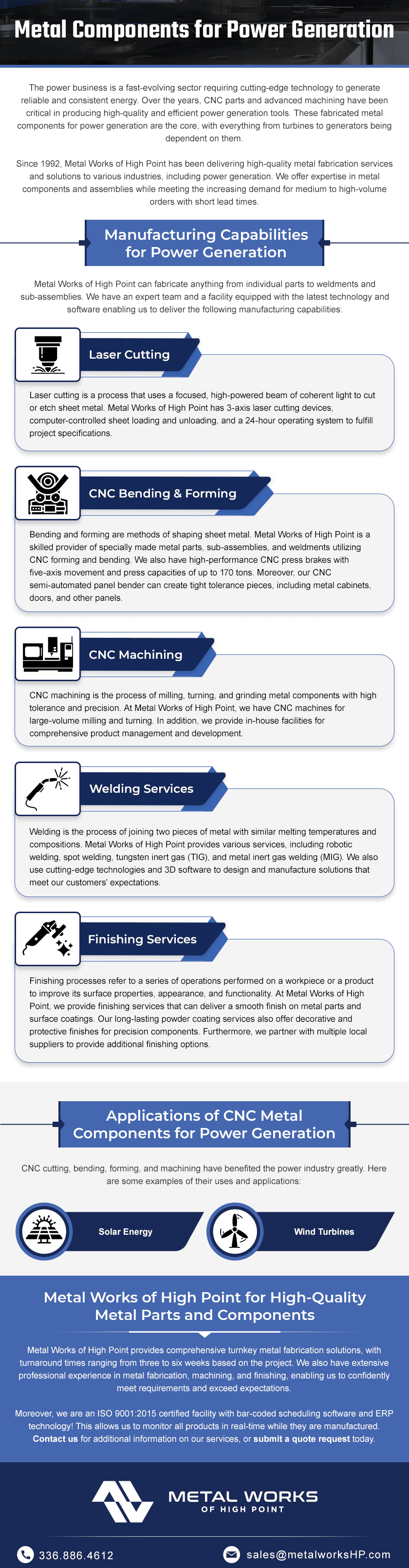

The power business is a fast-evolving sector requiring cutting-edge technology to generate reliable and consistent energy. Over the years, CNC parts and advanced machining have been critical in producing high-quality and efficient power generation tools. These fabricated metal components for power generation are the core, with everything from turbines to generators being dependent on them.

Since 1992, Metal Works of High Point has been delivering high-quality metal fabrication services and solutions to various industries, including power generation. We offer expertise in metal components and assemblies while meeting the increasing demand for medium to high-volume orders with short lead times.

Manufacturing Capabilities for Power Generation

Metal Works of High Point can fabricate anything from individual parts to weldments and sub-assemblies. We have an expert team and a facility equipped with the latest technology and software enabling us to deliver the following manufacturing capabilities:

Laser Cutting

Laser cutting is a process that uses a focused, high-powered beam of coherent light to cut or etch sheet metal. Metal Works of High Point has 3-axis laser cutting devices, computer-controlled sheet loading and unloading, and a 24-hour operating system to fulfill project specifications.

CNC Bending & Forming

Bending and forming are methods of shaping sheet metal. Metal Works of High Point is a skilled provider of specially made metal parts, sub-assemblies, and weldments utilizing CNC forming and bending. We also have high-performance CNC press brakes with five-axis movement and press capacities of up to 170 tons. Moreover, our CNC semi-automated panel bender can create tight tolerance pieces, including metal cabinets, doors, and other panels.

CNC Machining

CNC machining is the process of milling, turning, and grinding metal components with high tolerance and precision. At Metal Works of High Point, we have CNC machines for large-volume milling and turning. In addition, we provide in-house facilities for comprehensive product management and development.

Welding Services

Welding is the process of joining two pieces of metal with similar melting temperatures and compositions. Metal Works of High Point provides various services, including robotic welding, spot welding, tungsten inert gas (TIG), and metal inert gas welding (MIG). We also use cutting-edge technologies and 3D software to design and manufacture solutions that meet our customers’ expectations.

Finishing Services

Finishing processes refer to a series of operations performed on a workpiece or a product to improve its surface properties, appearance, and functionality. At Metal Works of High Point, we provide finishing services that can deliver a smooth finish on metal parts and surface coatings. Our long-lasting powder coating services also offer decorative and protective finishes for precision components. Furthermore, we partner with multiple local suppliers to provide additional finishing options.

Applications of CNC Metal Components for Power Generation

CNC cutting, bending, forming, and machining have benefited the power industry greatly. Here are some examples of their uses and applications:

Solar Energy

Milling and drilling machines are extensively used to fabricate solar products and components with exceptional precision. Major solar panel manufacturers employ CNC processes like cutting and perforating with non-CNC methods to improve their products’ quality and efficiency. In addition, turning centers and wire cutters are used for creating housing and frames.

Some fabricated metal components for power generation include panel frames, back rails, carrier rails, and mounting brackets.

Wind Turbines

In wind energy production, it is paramount to have parts and components that are robust enough to withstand extreme conditions while also maintaining precision. For instance, a gear-driven Nacelle turbine requires 8,000 subcomponents and spare parts. This can be manufactured quickly using metalworking techniques such as fabrication, machining, forging, and casting via CNC.

One critical component of wind turbines is the blades, which must withstand wind pressure while minimizing wear and tear. With CNC technology, manufacturers can produce large bearings for the adjustment mechanism of wind turbines with the same precision as for smaller components. Drilling machines are also frequently used to process holes in tube shell heat exchangers.

The most commonly used metal components in wind turbines are gears, gearbox housings, rotors, shafts, generator frames, and brake components.

Metal Works of High Point for High-Quality Metal Parts and Components

Metal Works of High Point provides comprehensive turnkey metal fabrication solutions, with turnaround times ranging from three to six weeks based on the project. We also have extensive professional experience in metal fabrication, machining, and finishing, enabling us to confidently meet requirements and exceed expectations.

Moreover, we are an ISO 9001:2015 certified facility with bar-coded scheduling software and ERP technology! This allows us to monitor all products in real-time while they are manufactured. Contact us for additional information on our services, or submit a quote request today.