Wet Paint vs. Powder Coatings

Since 1992, Metal Works of High Point has provided durable powder coating services for various industries and applications. To help our customers better understand the difference between powder coat vs. paint, we will focus on the suitability, benefits, and cost-effectiveness of these processes for industrial use.

Wet Paint vs. Powder Coatings

There are several factors to consider when choosing between wet paint and powder coatings. We cover some of the top considerations below.

What Is Wet Paint?

Wet paint is easy to apply and is the most affordable coating option available. In this process, a pressure sprayer applies a liquid solvent containing suspended color particles to a dry metal surface.

Both powder coating and the wet paint process can cover an entire surface. However, with wet painting, the painted metal does not need to be heated for curing. As the metal dries, the solvent evaporates. While the drying process is considerably longer with wet paint, it does not require any heating equipment.

Process

This versatile process is used to adhere liquid paint to a metal surface. Unlike wall painting, wet paint in an industrial setting utilizes a pump, spray, or pressurized vessel to achieve an even coating. Several paint layers may be needed, resulting in more time and labor costs compared to powder coating.

Benefits

- Easy Color Matching. Wet paint offers superior color-matching capabilities, making precise touchups easier.

- More Color Options. Mixing wet paint creates more color options than the limited pigments available for powder coatings.

- Self-Drying Products. Wet paint can dry without needing additional equipment, which is ideal for finishing products that cannot withstand heat treatments.

- Ideal Coating Thickness. Unlike powder coatings, wet paint can be applied in thin layers, accommodating metal pieces that must fit together.

- Greater Accessibility. Wet painting is more accessible than powder coating, as it does not require high-tech, expensive equipment to achieve desired results.

What Is Powder Coating?

Powder coating is made of finely ground particles of colored acrylics, polyurethane, or polyesters. The material is given a positive charge and dry-sprayed directly onto metal products that have received a negative charge. The process results in statically charged colored particles that cling to the negatively charged metal.

Once a metal product receives a uniform coat of the desired thickness, it is rapidly heated to cure and melt the powder to the metal. This curing and heating process typically takes about 10 minutes, depending on product size.

Process

Powder coating requires the application of a dry, free-floating organic powder via electrostatic attraction. To ensure an even coating, the piece must first be thoroughly cleaned.

The powder can consist of the following materials:

- Acrylic

- Epoxy

- Polyester

- Polyester-Epoxy

- Polyurethane

Benefits

- Color Retention. Powder coating allows the colors to stay truer longer than wet paint.

- Durability. Once set, powder is stronger than wet paint and can resist corrosion, rust, and damage, offering a more uniform coating that lasts.

- Low Maintenance. Powder coating only requires routine washing with soap and water, eliminating the need for harsh chemicals.

- Variety of Texture Materials. Powder provides more texture options than other coatings and is ideal for steps, ramps, and other metal products.

- Coating Consistency. The process ensures even, smooth finishes without application marks.

- Efficiency. Since powder particles are easily attracted to the metal surface, very little powder gets lost to over-spraying, making powder coating more efficient than wet paint. The process only requires one quick application with minimal drying time.

- Environmentally Friendly. Powder that falls to the ground can be reused, significantly reducing waste. The particles do not contain volatile organic compounds often found in paints, making the coating a more sustainable option.

Quality Coating Services by Metal Works

Metal Works of High Point Inc. offers reliable powder coating services that promote high-quality protective and decorative finishes in precision components. Contact us for more details about our manufacturing capabilities and learn how our services can meet the demands of your specific application.

Technical Comparison: Manual vs. Robotic Metal Welding

Metal Works of High Point has a long-standing reputation for delivering top-quality metal fabrication services. We offer manual and robotic welding solutions tailored to meet diverse project needs.

Today, we’re taking a closer look at manual and robotic welding techniques. We’ll compare precision, costs, speed, and flexibility to help you determine the best welding method for your next project.

Precision

Manual Welding

Skilled welders bring a level of precision that is hard to match. Their expertise allows them to adapt to intricate joint shapes, varying weld thicknesses, and more challenging positions. This is particularly useful when working with complex or tight welds requiring real-time adjustments.

Robotic Welding

Robotic metal welding technology offers unmatched consistency and repeatability. Once programmed, they follow a precise path to produce identical welds every time.

Robots can operate tirelessly, delivering greater output while maintaining high-quality standards around the clock. This level of precision is ideal for high-volume production where uniformity is essential.

Costs

Manual Welding

The initial equipment cost for manual welding is relatively low. Still, labor costs can increase, especially for large projects or repetitive tasks requiring skilled welders. Ongoing expenses for maintenance and training are also necessary to ensure welders remain proficient with the latest techniques and safety standards.

Robotic Welding

Automation in fabrication can come with a high upfront cost, including the price of the robots and programming. However, the long-term cost savings are significant due to increased efficiency and reduced labor costs, as one operator can oversee multiple robots.

Precise welds also reduce material waste, leading to further savings over time.

Speed and Flexibility

Manual Welding

Manual welders require setup time and torch maneuvering. Fatigue can also impact their performance, increasing the chance of variation in weld quality and speed. Production speed ultimately depends on the welder’s skill level and the complexity of the task.

Manual welding consistently offers superior flexibility, allowing welders to adapt to different materials and specifications.

Robotic Welding

Robots excel in high-rate production environments, performing repetitive tasks at consistent speeds without slowing. This makes them ideal for projects requiring a high volume of uniform welds.

Still, robotic systems are less flexible overall than manual welders. They are best suited for tasks that demand consistency and repeatability over projects requiring frequent adjustments or custom welds.

Whether you’re looking for repeatability, flexibility, or speed, there’s a welding method for your project. Understanding the strengths and limitations of manual and robotic welding will allow you to make an informed decision that aligns with your project requirements and budget.

Welding Services From Metal Works of High Point

At Metal Works of High Point, we offer both manual and robotic welding services to cater to our clients’ unique needs. Whether you need skilled welders’ adaptability or robotic systems’ precision and efficiency, we have the expertise and technology to deliver exceptional results.

Request a quote to learn more about our welding services. Trust Metal Works of High Point to provide the high-quality welding solutions you need.

How to Choose the Right Metal Fabrication Provider

Choosing the best metal fabrication provider can be a challenging task; however, making the right selection is critical to the success and quality of your project. To ensure you find a metal fabrication provider that can effectively meet your needs, there are various important factors to consider. These range from their level of experience to the types of equipment used, certifications, customer service, and more.

Here, we’ll go over the key considerations to keep in mind when determining the right metal fabrication partner and why you can trust Metal Works of High Point for all your sheet metal fabrication needs.

Considerations for Choosing the Right Metal Fabrication Provider

When narrowing down your search for the right metal fabrication provider, it’s important to consider the following:

Track Record & Experience Level

Be sure to look into a potential provider’s history and level of experience. Newer companies may not have much experience working on your type of project, so look for a provider with a proven track record for meeting similar needs as yours. You’re more likely to get higher-quality service at a better price if you select a metal fabrication partner with a long history of successful projects.

At Metal Works of High Point, we’ve been providing turnkey contract metal fabrication services since 1992. Our decades of experience allow us to deliver quality metal fabrication solutions that align with our customers’ unique needs, no matter how complex. View a small sampling of our previous work here.

Equipment Selection

A provider’s metal fabrication equipment will often determine the efficiency and quality of your project. For this reason, choose a provider that has invested in the latest equipment and stays up-to-date with the industry’s technological advancements. Metal Works of High Point is committed to innovation and uses state-of-the-art equipment and software to ensure precise, high-quality fabricated products.

Customer Service

Customer service is crucial when it comes to building a long-term relationship with your metal fabrication partner. Be sure to talk with prospective providers about common issues they’ve encountered in the past and how they were resolved. The right partner will provide responsive communication throughout the duration of your project and be transparent when it comes to pricing and timelines.

Metal Works of High Point takes a personalized approach to every project. With a focus on respect, honesty, and top-notch customer service, we can deliver the metal fabrication solutions you need while maintaining open, responsive communication.

Workforce Size & Expertise

It’s important to consider the size and expertise of a fabricator’s workforce. Companies with smaller teams may have a difficult time completing your project on time. It is also critical to ensure your fabricator’s team is composed of highly skilled and qualified craftsmen who can deliver high-quality work.

At Metal Works of High Point, our expert team brings hundreds of years of combined experience to every project. In addition to investing in the latest technology, we also invest in the training and education that goes with it to guarantee we’re providing the best possible solutions.

Certifications & Adherence to Quality Standards

Choose a metal fabrication provider that holds relevant certifications and adheres to high standards for quality. A company that values quality will be more equipped to deliver fabricated parts that meet or exceed expectations. Metal Works of High Point is ISO 9001:2015 certified, and we hold ourselves to the highest quality standards to ensure we provide superior products. In addition to our ISO certification, all of our welders are D1.3 certified.

In-House Finishing Capabilities

Look for a company that goes beyond initial construction by offering a range of finishing capabilities. Choosing a fabricator that can handle your project from start to finish saves time and money while ensuring consistency throughout the entire process.

At Metal Works of High Point, our capabilities extend to in-house powder coating and metal finishing services. This allows us to deliver completely finished products that meet your decorative and protective requirements.

Choose Metal Works of High Point—We Check Every Box

Metal Works of High Point has extensive experience providing top-quality metal fabrication services, including laser cutting, CNC forming, CNC machining, and welding. We also offer in-house powder coating and a range of other finishing services to protect your fabricated components.

From our ISO 9001:2015-certified facility, we can deliver the sheet metal fabrication solutions you need while meeting rigorous quality standards. For more information about our specific capabilities, or to work with us on your next project, contact us or request a quote today.

Advantages of In-House Powder Coating in OEM Metal Parts

At Metal Works of High Point, Inc., we pride ourselves on being a premier manufacturer of custom-fabricated metal components and assemblies. We offer a range of manufacturing capabilities and fine-tune our powder coating and finishing services to meet the evolving needs of our customers.

This article explores the benefits of powder coating and its growing impact on quality control, cost savings, and overall efficiency.

What is In-House Powder Coating?

Powder coating involves applying dry paint to a surface. Unlike traditional wet paint applications, powder coating involves spraying a solid powder coating directly onto the base material to create a hard, highly protective layer. This reliable, cost-effective method is widely used in different industries.

The powder used in this process is made from finely ground pigments and resin that are electrostatically charged and then sprayed onto the grounded metal parts. The charged powder particles cling to the metal surface, allowing for even coverage with minimal waste.

The parts are then cured in an oven to melt the powder into a smooth, aesthetically pleasing finish. This process is environmentally friendly, producing fewer volatile organic compounds (VOCs) than traditional liquid coatings.

Advantages of In-House Powder Coating in OEM Metal Parts

Cost Savings

Keeping powder coating services in-house allows for more accurate project quoting, eliminating unexpected expenses and additional markups. We work to fully understand project requirements and realize cost-effective in-house powder coating solutions that meet your specific needs.

We intentionally reduce our dependence on third-party schedules, mitigating the potential delays and additional costs associated with outsourcing. We then pass these cost savings on to our customers.

Quality Control

Outsourcing powder coating can compromise quality control, especially with metal finishing projects. Offsite processes often result in surface imperfections and uneven paint coverage, particularly with gloss finishes.

Our in-house powder coating specialists can identify and address these issues before painting. This close supervision prevents problems like color mismatches and non-uniform thickness, resulting in a high-quality finish.

Having an in-house team also allows for continuous improvement and fine-tuning of the process, ensuring that the highest standards are consistently met and client needs are met.

Reduction of Waste & Rework

Offsite powder coating often leads to overlooked imperfections, only discovered after returning to the fabricator, increasing lead time and costs. Shipping metal parts to and from an offsite vendor can cause damage, further adding to waste and rework.

Specialists at our metal fabrication facility can quickly detect and correct defects before painting, reducing waste and rework and maintaining the integrity of the parts used in the fabrication process. Our streamlined approach reduces material wastage and minimizes environmental impact for more sustainable manufacturing practices.

Speed & Efficiency

Outsourcing powder coating extends lead times and can delay product delivery by days or even weeks. With in-house powder coating, the fabrication process can be completed in as little as a day depending on order size.

Outsourcing powder coatings also creates fluctuations in lead times. When you choose in-house powder coating, you can count on us to deliver finished products faster than the competition.

Customer Service & Satisfaction

In-house powder coating allows fabrication teams to oversee the entire project from start to finish. This direct management results in higher-quality manufacturing outcomes.

Investing in in-house powder coating is a significant value-add for fabricators committed to offering clients better service and superior products. This approach guarantees that any issues are promptly communicated and addressed. Customer feedback is directly integrated into the process, fostering a collaborative and responsive service environment.

Conclusion

In-house powder coating offers numerous advantages, including cost savings, improved quality control, reduced waste and rework, and faster turnaround times. At Metal Works of High Point, we’re equipped to handle all your custom finishing needs, including high-quality decorative or protective finishes fabricated to your exact specifications.

For more information about our custom finishing capabilities, contact us. You can also request a quote based on your project’s requirements.

Choosing the Right Sheet Metal Materials

Sheet metal is a thin, flat sheet formed through an industrial process. It is versatile as it can be cut or bent into various shapes to make everyday objects. When fabricating sheet metal, there are a lot of different metals to choose from. And while they may all look like thin sheets of metal, the materials are what makes each sheet of metal unique.

Different Sheet Metal Materials

Each type of metal has specific properties that set it apart and give it an advantage over other metals for specific projects. There are seven common types of sheet metal materials for sheet metal fabrication:

Aluminum

Aluminum is an excellent option for applications that require a lightweight material. This sheet metal material offers reliable corrosion resistance even without a finish. It is also widely used for fabrication because it is strong and can undergo laser cutting, welding, and machining. Overall, aluminum is a moderately-priced material with various characteristics across several grades to meet different application requirements.

Carbon Steel

This sheet metal material is a product of iron alloyed with carbon. It features high amounts of strength with options of low, medium, or high carbon contents, depending on the desired application. Higher levels of carbon usually result in a more fragile product, and carbon steel with lower amounts of carbon is more sturdy, making it a preferred choice for creating fences or gates. Meanwhile, carbon steel with mid-level carbon is favored for automotive vehicles and appliances.

Alloy Steel

Alloy steel combines different elements, with carbon steel as the main component. The common metals added to form alloy steel are tungsten, chromium, and manganese if a sheet metal fabricator aims to achieve rigidity. But if the goal is strength, vanadium or nickel is added. Overall, this sheet metal material is highly versatile and affordable.

Tool Steel

Tool steel is also a very versatile sheet metal material and is rigid as it only contains 1% carbon. Like alloy steel, tool steel combines different mixed and matched metals to exploit a particular characteristic. Aside from rigidity, the other advantages of tool steel are its resistance to abrasion and outstanding performance under extreme temperatures. Because of its properties, this sheet metal material is famously used for construction tools like blades, hammers, dies, and punches.

Galvanized Steel

Galvanized steel can be classified into electro-galvanized sheets or hot-dipped metallic-coated sheets. Electro-galvanized sheets are made from cold-rolled annealed steel with a pure zinc coating with no zinc spangle. Meanwhile, a hot-dipped metallic-coated sheet is made from cold-rolled rigid steel plates and coated with pure zinc and an iron-zinc alloy. Hot-dipped metallic coated sheets have more corrosion resistance and are more affordable than electro-galvanized metal sheets.

Stainless Steel

This sheet metal material works great for products constantly exposed to moisture. It contains chromium, which gives it excellent corrosion resistance against harsh or damp environments. Because of this characteristic, kitchen and office products made from stainless steel sheet metal usually have a longer lifespan.

Cold-Rolled Steel

Cold-rolled steel is made in cold-reduction mills. This material is cooled near room temperature, followed by annealing or rolling tempers. It also has a wide range of surface finishes and possesses excellent tolerance, concentricity, and straightness.

Key Factors To Consider When Selecting a Sheet Metal Material

Selecting a suitable sheet metal for your project is crucial as it determines whether the fabricated component or parts will perform faultlessly. Here are some key factors to consider:

Size and Application of the Component

Knowing the component’s size and intended use is essential when selecting a sheet metal material. Keeping these factors in mind will help you determine how strong the piece needs to be and which sheet metal material is the most applicable in its use-case scenario. For example, aerospace industry components require a sheet metal material with an excellent strength-to-weight ratio.

Design and Tolerance Requirements

When choosing a sheet metal material, the design and tolerance requirements of the component you manufacture are essential to keep in mind. Wall thickness, bend allowance, K-factor, and the orientation of holes and slots are some elements that will influence your choice.

Compatibility With Manufacturing Processes

The manufacturing process also dictates which sheet metal material is suitable for the job. The sheet metal material must withstand the manufacturing process, including laser cutting,

Compatibility With Common Fabrication Methods

As with manufacturing processes, the chosen sheet metal material must also be compatible with standard fabrication methods used to finish corners, close gaps, and enhance or maintain the shape and integrity of a component. TIG welding, MIG welding, riveting, and brazing are typical fabrication methods.

Learn More About Sheet Metal Materials From Metal Works

We at Metal Works of High Point have a team of experts with a hundred years of combined experience to provide you with a responsive and personalized service! We also offer state-of-the-art equipment and software that deliver precise and high-quality products.

Metal Works’ ISO 9001: 2015 Certified facility features bar-coded scheduling software and ERP technology, enabling us to get a real-time view of your product while it is manufacturing. Moreover, our capabilities grant us the knowledge and expertise to guide you through any questions or concerns that you may have about sheet metal materials.

Contact us today for your next metalworking project!

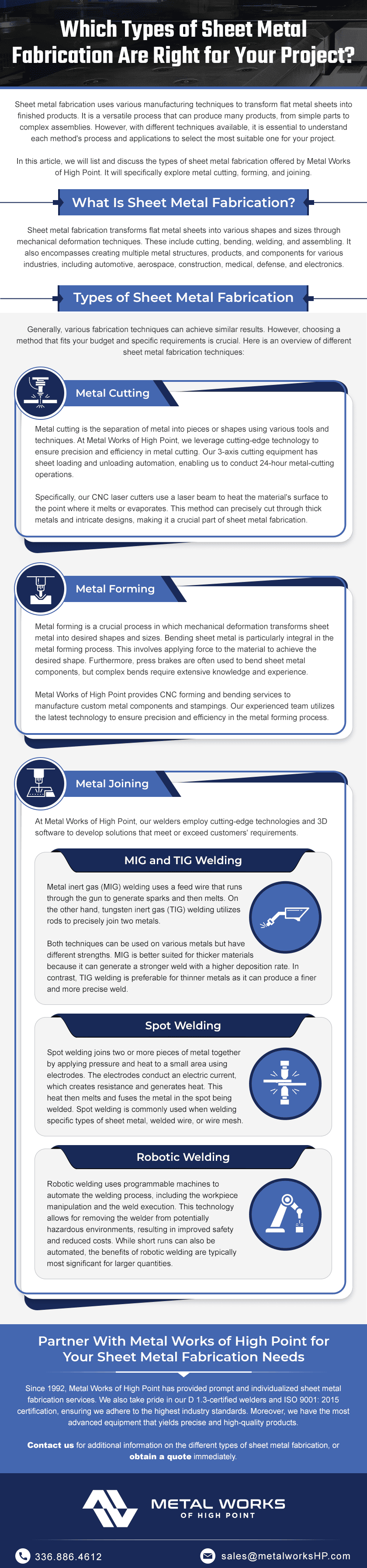

Which Type of Sheet Metal Fabrication Is Right for Your Project?

Sheet metal fabrication uses various manufacturing techniques to transform flat metal sheets into finished products. It is a versatile process that can produce many products, from simple parts to complex assemblies. However, with different techniques available, it is essential to understand each method’s process and applications to select the most suitable one for your project.

In this article, we will list and discuss the types of sheet metal fabrication offered by Metal Works of High Point. It will specifically explore metal cutting, forming, and joining.

What Is Sheet Metal Fabrication?

Sheet metal fabrication transforms flat metal sheets into various shapes and sizes through mechanical deformation techniques. These include cutting, bending, welding, and assembling. It also encompasses creating multiple metal structures, products, and components for various industries, including automotive, aerospace, construction, medical, defense, and electronics.

Types of Sheet Metal Fabrication

Generally, various fabrication techniques can achieve similar results. However, choosing a method that fits your budget and specific requirements is crucial. Here is an overview of different sheet metal fabrication techniques:

Metal Cutting

Metal cutting is the separation of metal into pieces or shapes using various tools and techniques. At Metal Works of High Point, we leverage cutting-edge technology to ensure precision and efficiency in metal cutting. Our 3-axis cutting equipment has sheet loading and unloading automation, enabling us to conduct 24-hour metal-cutting operations.

Specifically, our CNC laser cutters use a laser beam to heat the material’s surface to the point where it melts or evaporates. This method can precisely cut through thick metals and intricate designs, making it a crucial part of sheet metal fabrication.

Metal Forming

Metal forming is a crucial process in which mechanical deformation transforms sheet metal into desired shapes and sizes. Bending sheet metal is particularly integral in the metal forming process. This involves applying force to the material to achieve the desired shape. Furthermore, press brakes are often used to bend sheet metal components, but complex bends require extensive knowledge and experience.

Metal Works of High Point provides CNC forming and bending services to manufacture custom metal components and stampings. Our experienced team utilizes the latest technology to ensure precision and efficiency in the metal forming process.

Metal Joining

At Metal Works of High Point, our welders employ cutting-edge technologies and 3D software to develop solutions that meet or exceed customers’ requirements.

MIG and TIG Welding

Metal inert gas (MIG) welding uses a feed wire that runs through the gun to generate sparks and then melts. On the other hand, tungsten inert gas (TIG) welding utilizes rods to precisely join two metals.

Both techniques can be used on various metals but have different strengths. MIG is better suited for thicker materials because it can generate a stronger weld with a higher deposition rate. In contrast, TIG welding is preferable for thinner metals as it can produce a finer and more precise weld.

Spot Welding

Spot welding joins two or more pieces of metal together by applying pressure and heat to a small area using electrodes. The electrodes conduct an electric current, which creates resistance and generates heat. This heat then melts and fuses the metal in the spot being welded. Spot welding is commonly used when welding specific types of sheet metal, welded wire, or wire mesh.

Robotic Welding

Robotic welding uses programmable machines to automate the welding process, including the workpiece manipulation and the weld execution. This technology allows for removing the welder from potentially hazardous environments, resulting in improved safety and reduced costs. While short runs can also be automated, the benefits of robotic welding are typically most significant for larger quantities.

Partner With Metal Works of High Point for Your Sheet Metal Fabrication Needs

Since 1992, Metal Works of High Point has provided prompt and individualized sheet metal fabrication services. We also take pride in our D 1.3-certified welders and ISO 9001: 2015 certification, ensuring we adhere to the highest industry standards. Moreover, we have the most advanced equipment that yields precise and high-quality products.

Contact us for additional information on the different types of sheet metal fabrication, or obtain a quote immediately.