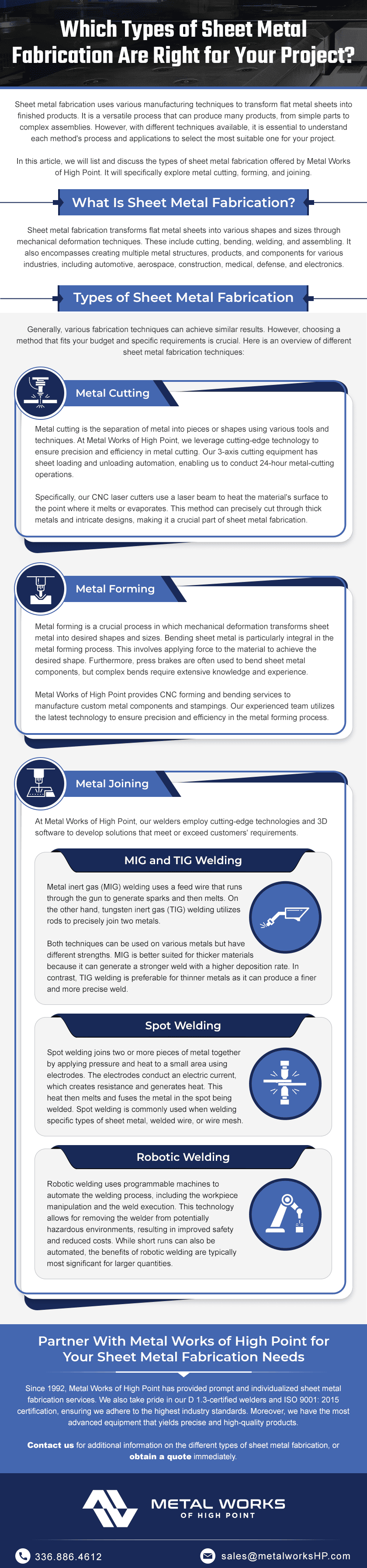

Sheet metal fabrication uses various manufacturing techniques to transform flat metal sheets into finished products. It is a versatile process that can produce many products, from simple parts to complex assemblies. However, with different techniques available, it is essential to understand each method’s process and applications to select the most suitable one for your project.

In this article, we will list and discuss the types of sheet metal fabrication offered by Metal Works of High Point. It will specifically explore metal cutting, forming, and joining.

What Is Sheet Metal Fabrication?

Sheet metal fabrication transforms flat metal sheets into various shapes and sizes through mechanical deformation techniques. These include cutting, bending, welding, and assembling. It also encompasses creating multiple metal structures, products, and components for various industries, including automotive, aerospace, construction, medical, defense, and electronics.

Types of Sheet Metal Fabrication

Generally, various fabrication techniques can achieve similar results. However, choosing a method that fits your budget and specific requirements is crucial. Here is an overview of different sheet metal fabrication techniques:

Metal Cutting

Metal cutting is the separation of metal into pieces or shapes using various tools and techniques. At Metal Works of High Point, we leverage cutting-edge technology to ensure precision and efficiency in metal cutting. Our 3-axis cutting equipment has sheet loading and unloading automation, enabling us to conduct 24-hour metal-cutting operations.

Specifically, our CNC laser cutters use a laser beam to heat the material’s surface to the point where it melts or evaporates. This method can precisely cut through thick metals and intricate designs, making it a crucial part of sheet metal fabrication.

Metal Forming

Metal forming is a crucial process in which mechanical deformation transforms sheet metal into desired shapes and sizes. Bending sheet metal is particularly integral in the metal forming process. This involves applying force to the material to achieve the desired shape. Furthermore, press brakes are often used to bend sheet metal components, but complex bends require extensive knowledge and experience.

Metal Works of High Point provides CNC forming and bending services to manufacture custom metal components and stampings. Our experienced team utilizes the latest technology to ensure precision and efficiency in the metal forming process.

Metal Joining

At Metal Works of High Point, our welders employ cutting-edge technologies and 3D software to develop solutions that meet or exceed customers’ requirements.

MIG and TIG Welding

Metal inert gas (MIG) welding uses a feed wire that runs through the gun to generate sparks and then melts. On the other hand, tungsten inert gas (TIG) welding utilizes rods to precisely join two metals.

Both techniques can be used on various metals but have different strengths. MIG is better suited for thicker materials because it can generate a stronger weld with a higher deposition rate. In contrast, TIG welding is preferable for thinner metals as it can produce a finer and more precise weld.

Spot Welding

Spot welding joins two or more pieces of metal together by applying pressure and heat to a small area using electrodes. The electrodes conduct an electric current, which creates resistance and generates heat. This heat then melts and fuses the metal in the spot being welded. Spot welding is commonly used when welding specific types of sheet metal, welded wire, or wire mesh.

Robotic Welding

Robotic welding uses programmable machines to automate the welding process, including the workpiece manipulation and the weld execution. This technology allows for removing the welder from potentially hazardous environments, resulting in improved safety and reduced costs. While short runs can also be automated, the benefits of robotic welding are typically most significant for larger quantities.

Partner With Metal Works of High Point for Your Sheet Metal Fabrication Needs

Since 1992, Metal Works of High Point has provided prompt and individualized sheet metal fabrication services. We also take pride in our D 1.3-certified welders and ISO 9001: 2015 certification, ensuring we adhere to the highest industry standards. Moreover, we have the most advanced equipment that yields precise and high-quality products.

Contact us for additional information on the different types of sheet metal fabrication, or obtain a quote immediately.