Choosing the Right Sheet Metal Materials

Leave a CommentSheet metal is a thin, flat sheet formed through an industrial process. It is versatile as it can be cut or bent into various shapes to make everyday objects. When fabricating sheet metal, there are a lot of different metals to choose from. And while they may all look like thin sheets of metal, the materials are what makes each sheet of metal unique.

Different Sheet Metal Materials

Each type of metal has specific properties that set it apart and give it an advantage over other metals for specific projects. There are seven common types of sheet metal materials for sheet metal fabrication:

Aluminum

Aluminum is an excellent option for applications that require a lightweight material. This sheet metal material offers reliable corrosion resistance even without a finish. It is also widely used for fabrication because it is strong and can undergo laser cutting, welding, and machining. Overall, aluminum is a moderately-priced material with various characteristics across several grades to meet different application requirements.

Carbon Steel

This sheet metal material is a product of iron alloyed with carbon. It features high amounts of strength with options of low, medium, or high carbon contents, depending on the desired application. Higher levels of carbon usually result in a more fragile product, and carbon steel with lower amounts of carbon is more sturdy, making it a preferred choice for creating fences or gates. Meanwhile, carbon steel with mid-level carbon is favored for automotive vehicles and appliances.

Alloy Steel

Alloy steel combines different elements, with carbon steel as the main component. The common metals added to form alloy steel are tungsten, chromium, and manganese if a sheet metal fabricator aims to achieve rigidity. But if the goal is strength, vanadium or nickel is added. Overall, this sheet metal material is highly versatile and affordable.

Tool Steel

Tool steel is also a very versatile sheet metal material and is rigid as it only contains 1% carbon. Like alloy steel, tool steel combines different mixed and matched metals to exploit a particular characteristic. Aside from rigidity, the other advantages of tool steel are its resistance to abrasion and outstanding performance under extreme temperatures. Because of its properties, this sheet metal material is famously used for construction tools like blades, hammers, dies, and punches.

Galvanized Steel

Galvanized steel can be classified into electro-galvanized sheets or hot-dipped metallic-coated sheets. Electro-galvanized sheets are made from cold-rolled annealed steel with a pure zinc coating with no zinc spangle. Meanwhile, a hot-dipped metallic-coated sheet is made from cold-rolled rigid steel plates and coated with pure zinc and an iron-zinc alloy. Hot-dipped metallic coated sheets have more corrosion resistance and are more affordable than electro-galvanized metal sheets.

Stainless Steel

This sheet metal material works great for products constantly exposed to moisture. It contains chromium, which gives it excellent corrosion resistance against harsh or damp environments. Because of this characteristic, kitchen and office products made from stainless steel sheet metal usually have a longer lifespan.

Cold-Rolled Steel

Cold-rolled steel is made in cold-reduction mills. This material is cooled near room temperature, followed by annealing or rolling tempers. It also has a wide range of surface finishes and possesses excellent tolerance, concentricity, and straightness.

Key Factors To Consider When Selecting a Sheet Metal Material

Selecting a suitable sheet metal for your project is crucial as it determines whether the fabricated component or parts will perform faultlessly. Here are some key factors to consider:

Size and Application of the Component

Knowing the component’s size and intended use is essential when selecting a sheet metal material. Keeping these factors in mind will help you determine how strong the piece needs to be and which sheet metal material is the most applicable in its use-case scenario. For example, aerospace industry components require a sheet metal material with an excellent strength-to-weight ratio.

Design and Tolerance Requirements

When choosing a sheet metal material, the design and tolerance requirements of the component you manufacture are essential to keep in mind. Wall thickness, bend allowance, K-factor, and the orientation of holes and slots are some elements that will influence your choice.

Compatibility With Manufacturing Processes

The manufacturing process also dictates which sheet metal material is suitable for the job. The sheet metal material must withstand the manufacturing process, including laser cutting,

Compatibility With Common Fabrication Methods

As with manufacturing processes, the chosen sheet metal material must also be compatible with standard fabrication methods used to finish corners, close gaps, and enhance or maintain the shape and integrity of a component. TIG welding, MIG welding, riveting, and brazing are typical fabrication methods.

Learn More About Sheet Metal Materials From Metal Works

We at Metal Works of High Point have a team of experts with a hundred years of combined experience to provide you with a responsive and personalized service! We also offer state-of-the-art equipment and software that deliver precise and high-quality products.

Metal Works’ ISO 9001: 2015 Certified facility features bar-coded scheduling software and ERP technology, enabling us to get a real-time view of your product while it is manufacturing. Moreover, our capabilities grant us the knowledge and expertise to guide you through any questions or concerns that you may have about sheet metal materials.

Contact us today for your next metalworking project!

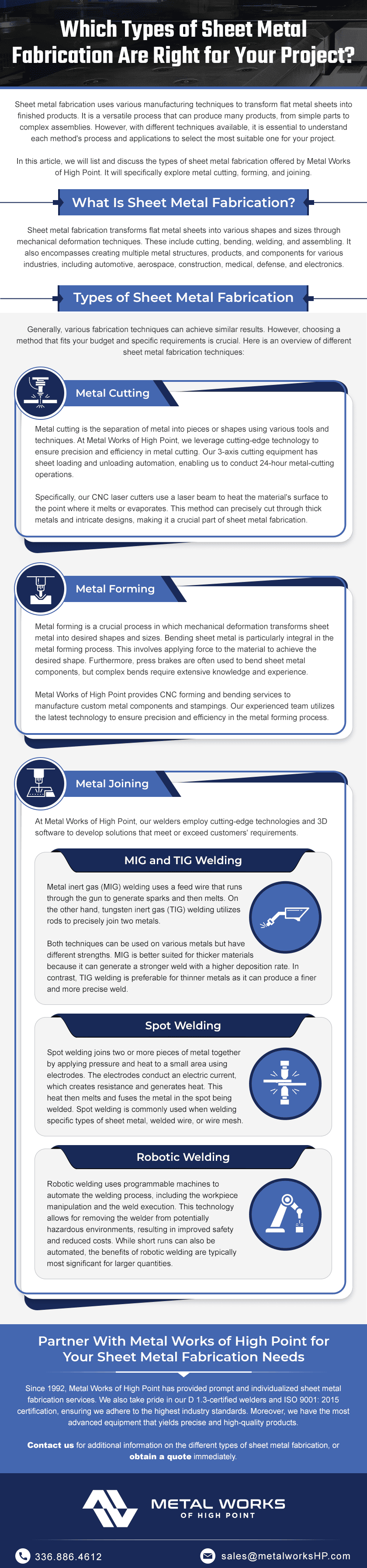

Which Type of Sheet Metal Fabrication Is Right for Your Project?

Leave a CommentSheet metal fabrication uses various manufacturing techniques to transform flat metal sheets into finished products. It is a versatile process that can produce many products, from simple parts to complex assemblies. However, with different techniques available, it is essential to understand each method’s process and applications to select the most suitable one for your project.

In this article, we will list and discuss the types of sheet metal fabrication offered by Metal Works of High Point. It will specifically explore metal cutting, forming, and joining.

What Is Sheet Metal Fabrication?

Sheet metal fabrication transforms flat metal sheets into various shapes and sizes through mechanical deformation techniques. These include cutting, bending, welding, and assembling. It also encompasses creating multiple metal structures, products, and components for various industries, including automotive, aerospace, construction, medical, defense, and electronics.

Types of Sheet Metal Fabrication

Generally, various fabrication techniques can achieve similar results. However, choosing a method that fits your budget and specific requirements is crucial. Here is an overview of different sheet metal fabrication techniques:

Metal Cutting

Metal cutting is the separation of metal into pieces or shapes using various tools and techniques. At Metal Works of High Point, we leverage cutting-edge technology to ensure precision and efficiency in metal cutting. Our 3-axis cutting equipment has sheet loading and unloading automation, enabling us to conduct 24-hour metal-cutting operations.

Specifically, our CNC laser cutters use a laser beam to heat the material’s surface to the point where it melts or evaporates. This method can precisely cut through thick metals and intricate designs, making it a crucial part of sheet metal fabrication.

Metal Forming

Metal forming is a crucial process in which mechanical deformation transforms sheet metal into desired shapes and sizes. Bending sheet metal is particularly integral in the metal forming process. This involves applying force to the material to achieve the desired shape. Furthermore, press brakes are often used to bend sheet metal components, but complex bends require extensive knowledge and experience.

Metal Works of High Point provides CNC forming and bending services to manufacture custom metal components and stampings. Our experienced team utilizes the latest technology to ensure precision and efficiency in the metal forming process.

Metal Joining

At Metal Works of High Point, our welders employ cutting-edge technologies and 3D software to develop solutions that meet or exceed customers’ requirements.

MIG and TIG Welding

Metal inert gas (MIG) welding uses a feed wire that runs through the gun to generate sparks and then melts. On the other hand, tungsten inert gas (TIG) welding utilizes rods to precisely join two metals.

Both techniques can be used on various metals but have different strengths. MIG is better suited for thicker materials because it can generate a stronger weld with a higher deposition rate. In contrast, TIG welding is preferable for thinner metals as it can produce a finer and more precise weld.

Spot Welding

Spot welding joins two or more pieces of metal together by applying pressure and heat to a small area using electrodes. The electrodes conduct an electric current, which creates resistance and generates heat. This heat then melts and fuses the metal in the spot being welded. Spot welding is commonly used when welding specific types of sheet metal, welded wire, or wire mesh.

Robotic Welding

Robotic welding uses programmable machines to automate the welding process, including the workpiece manipulation and the weld execution. This technology allows for removing the welder from potentially hazardous environments, resulting in improved safety and reduced costs. While short runs can also be automated, the benefits of robotic welding are typically most significant for larger quantities.

Partner With Metal Works of High Point for Your Sheet Metal Fabrication Needs

Since 1992, Metal Works of High Point has provided prompt and individualized sheet metal fabrication services. We also take pride in our D 1.3-certified welders and ISO 9001: 2015 certification, ensuring we adhere to the highest industry standards. Moreover, we have the most advanced equipment that yields precise and high-quality products.

Contact us for additional information on the different types of sheet metal fabrication, or obtain a quote immediately.

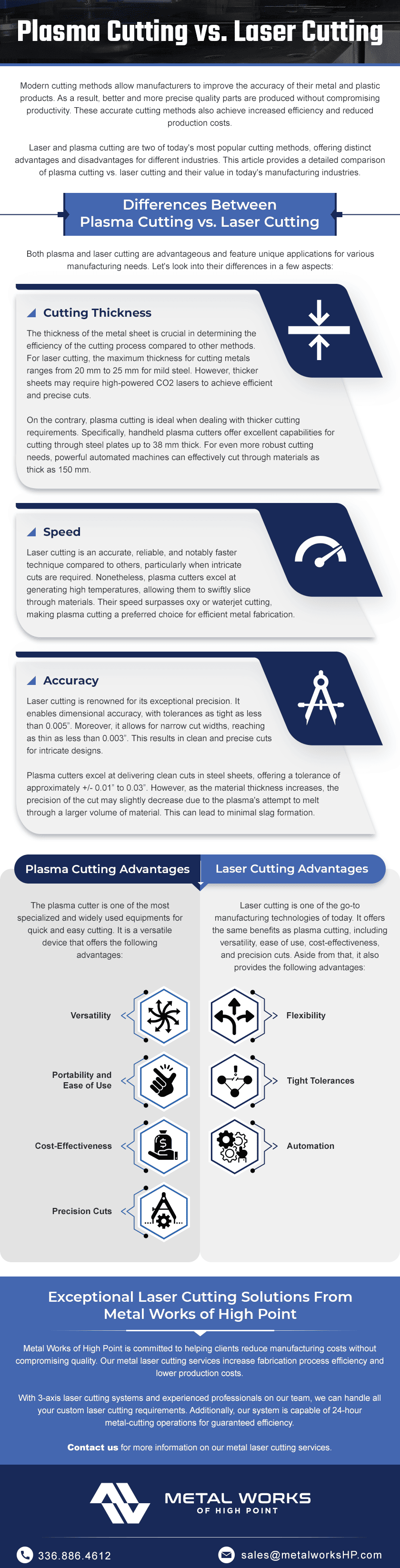

Plasma Cutting vs. Laser Cutting

Leave a CommentModern cutting methods allow manufacturers to improve the accuracy of their metal and plastic products. As a result, better and more precise quality parts are produced without compromising productivity. These accurate cutting methods also achieve increased efficiency and reduced production costs.

Laser and plasma cutting are two of today’s most popular cutting methods, offering distinct advantages and disadvantages for different industries. This article provides a detailed comparison of plasma cutting vs. laser cutting and their value in today’s manufacturing industries.

Differences Between Plasma Cutting vs. Laser Cutting

Both plasma and laser cutting are advantageous and feature unique applications for various manufacturing needs. Let’s look into their differences in a few aspects:

Cutting Thickness

The thickness of the metal sheet is crucial in determining the efficiency of the cutting process compared to other methods. For laser cutting, the maximum thickness for cutting metals ranges from 20 mm to 25 mm for mild steel. However, thicker sheets may require high-powered CO2 lasers to achieve efficient and precise cuts.

On the contrary, plasma cutting is ideal when dealing with thicker cutting requirements. Specifically, handheld plasma cutters offer excellent capabilities for cutting through steel plates up to 38 mm thick. For even more robust cutting needs, powerful automated machines can effectively cut through materials as thick as 150 mm.

Speed

Laser cutting is an accurate, reliable, and notably faster technique compared to others, particularly when intricate cuts are required. Nonetheless, plasma cutters excel at generating high temperatures, allowing them to swiftly slice through materials. Their speed surpasses oxy or waterjet cutting, making plasma cutting a preferred choice for efficient metal fabrication.

Accuracy

Laser cutting is renowned for its exceptional precision. It enables dimensional accuracy, with tolerances as tight as less than 0.005”. Moreover, it allows for narrow cut widths, reaching as thin as less than 0.003”. This results in clean and precise cuts for intricate designs.

Plasma cutters excel at delivering clean cuts in steel sheets, offering a tolerance of approximately +/- 0.01” to 0.03”. However, as the material thickness increases, the precision of the cut may slightly decrease due to the plasma’s attempt to melt through a larger volume of material. This can lead to minimal slag formation.

Plasma Cutting Advantages

The plasma cutter is one of the most specialized and widely used equipments for quick and easy cutting. It is a versatile device that offers the following advantages:

Versatility

Different kinds of metal can be cut with plasma. Likewise, any conductive metal — including steel, iron, copper, brass, aluminum, stainless steel, and other hard materials — can be cut using an electric arc. Plasma may also cut objects stacked on top of one another.

Portability and Ease of Use

Plasma cutters’ portability and ease of use make them highly practical and convenient tools for various applications. Due to their compact design and lightweight nature, plasma cutters can also be easily transported to different job sites.

Cost-Effectiveness

Plasma cutting is a cost-effective process with faster cutting speeds and minimal waste. This translates to lower consumer costs, making it more economical than other cutting techniques.

Precision Cuts

Plasma cutters excel in achieving precise and accurate cuts, particularly when working with sheet metal and intricate shapes. However, it does require skilled operators with steady hands to ensure optimal results.

Laser Cutting Advantages

Laser cutting is one of the go-to manufacturing technologies of today. It offers the same benefits as plasma cutting, including versatility, ease of use, cost-effectiveness, and precision cuts. Aside from that, it also provides the following advantages:

Flexibility

When using a laser cutter, switching out equipment between cuts is unnecessary. Several forms can be cut out of the same material thickness with the same configurations, including intricate cuts.

Tight Tolerances

One of the main benefits of laser cutting over other thermal cutting techniques is accuracy. With a +/-0.1 mm accuracy, great precision can be attained without post-treatment. Such a high quality typically negates the need for different tolerances.

Automation

Laser cutting can be highly automated, minimizing the need for manual labor. While an experienced operator contributes to the final product’s quality, the speed and efficiency of laser-cutting automation result in cost savings.

Exceptional Laser Cutting Solutions From Metal Works of High Point

Metal Works of High Point is committed to helping clients reduce manufacturing costs without compromising quality. Our metal laser cutting services increase fabrication process efficiency and lower production costs.

With 3-axis laser cutting systems and experienced professionals on our team, we can handle all your custom laser cutting requirements. Additionally, our system is capable of 24-hour metal-cutting operations for guaranteed efficiency.

Contact us for more information on our metal laser cutting services.