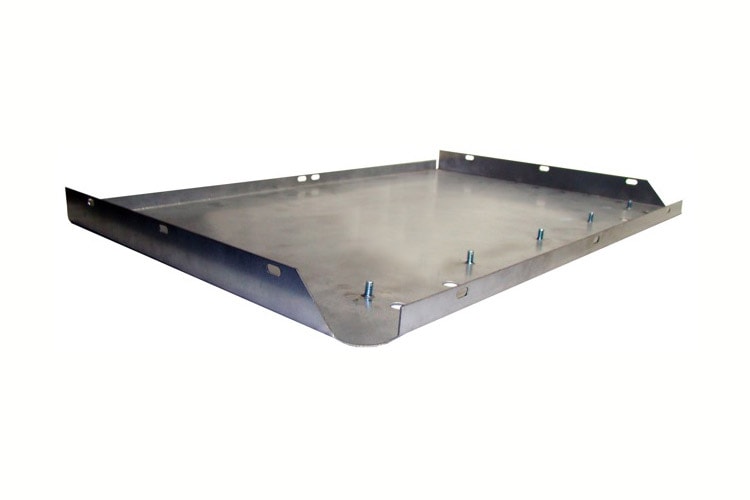

At Metal Works of High Point, Inc., we are able to use the latest design and fabrication technologies to take a customer’s project from drawing to reality. The part shown here is a matte black powder coated drip pan that we manufacture for a customer in the transportation industry. The pan is made of 18 gauge galvanneal steel that is punched, formed, turned, and welded to create the complete assembly. To accommodate the tight dimensional tolerances of ±0.010″ during the punching and bending operations, the assembly was first drawn in a 3D CAD modeling system. Careful analysis of a part prior to actual production allows us to select the proper tooling and fixtures for the project the first time, preventing costly scrapped parts and extended lead times due to retooling.

After the drip pan was analyzed in the modeling program, our engineering team selected the appropriate tooling and created the work procedures for the CNC punch cutting, press brake forming, and turning processes. The assembly is welded using a TIG welder to create an exceptionally clean weld, and the finished pan is powder coated with a 3 mil thick matte black polyurethane coating. Any time we weld coated metals, such as galvanized or galvanneal steel, additional precautions are taken to ensure the safety of our welders and the quality of the weld. The finished drip pan measures 24.625″ in length, 5.375″ in width, and 1″ in height. We manufacture approximately 250 of these assemblies per month with an average lead time of three weeks per order. For additional details regarding this custom metal fabrication project, see the table below, or contact us directly.