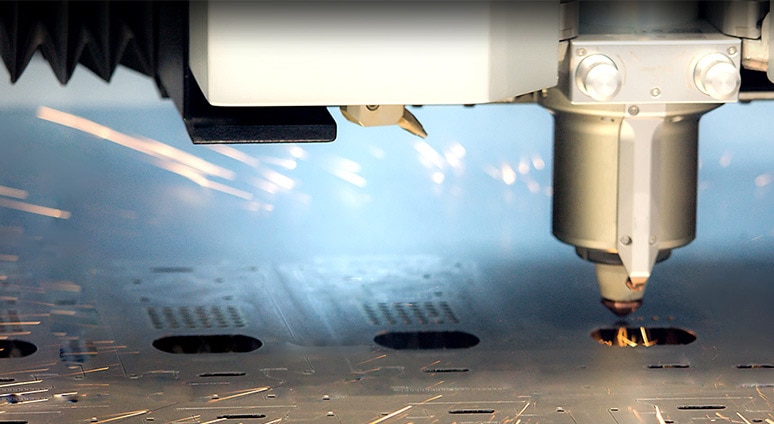

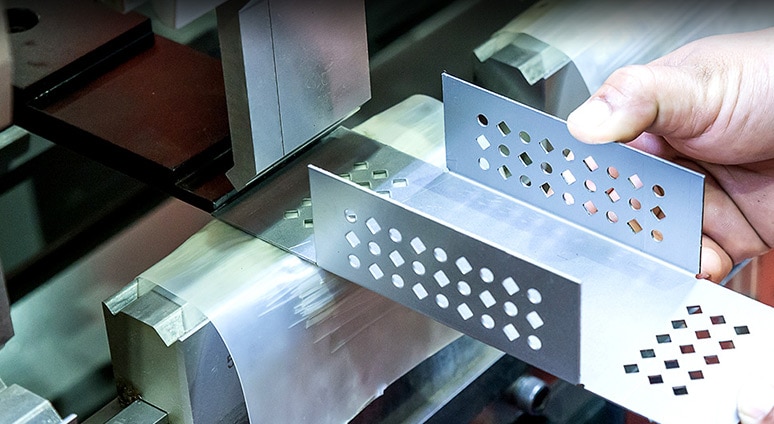

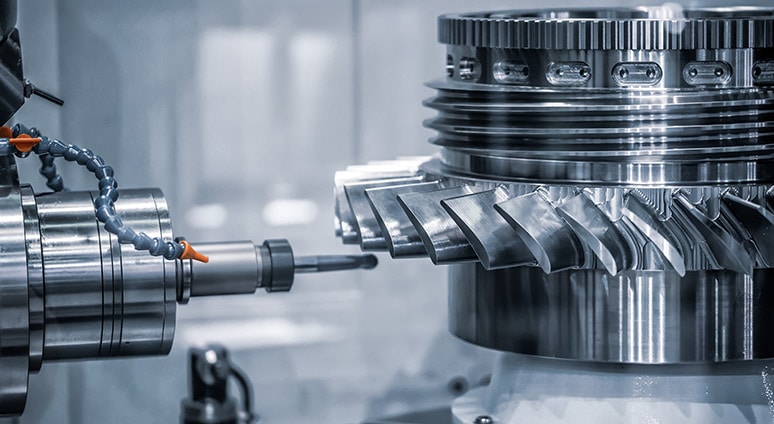

A Selection of Our Specialities

Industries Served

Handling

Furniture

Our Company History

About Us

Metal Works staff is committed to our core values and producing the highest quality metal products to meet your needs. We remain a second-generation, family-owned and operated company working hard to provide you with turnkey solutions for custom metal fabrication.