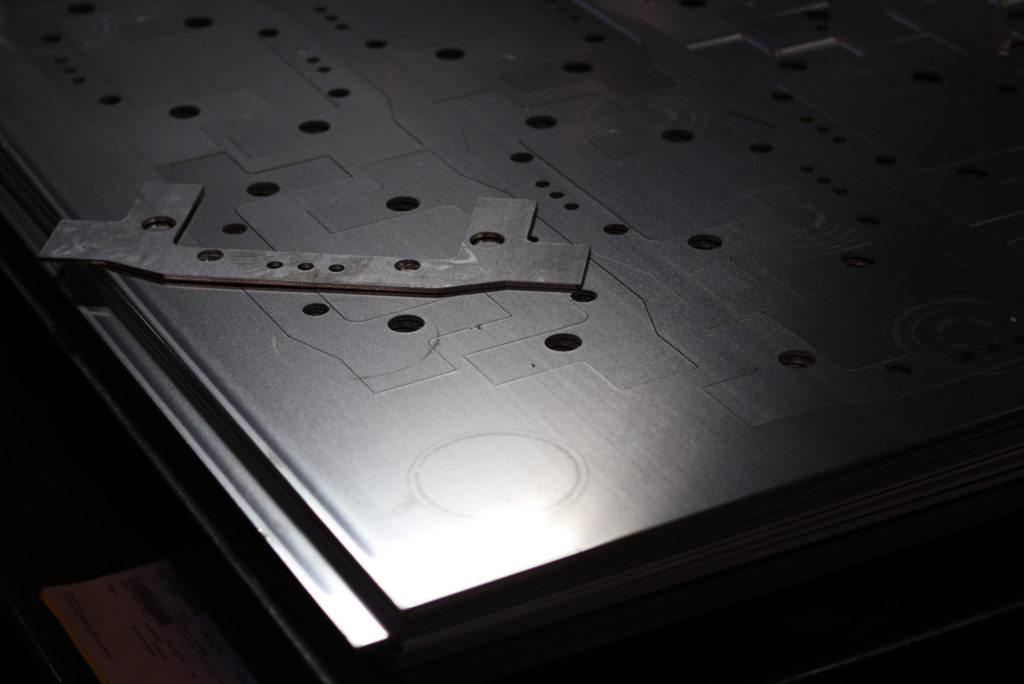

Lasers are extremely focused beams of light that can melt and disintegrate materials. They offer an extremely precise method for cutting or creating holes in a broad range of material types and thicknesses. Advanced computer numerical control (CNC) laser cutting machinery contributes to the fabrication of detailed and complex parts.

At Metal Works of High Point, we’re dedicated to helping our customers achieve cost reductions without reducing quality. Our metal laser cutting services help us to drive efficiency in our fabrication processes and reduce overall production costs.

What is Industrial Laser Cutting?

Laser cutting has become popular in industrial settings for its ability to create extremely accurate cuts with little or no waste.

CO2 lasers pass electricity through carbon dioxide and other gases to create a beam of light, which is focused and intensified with mirrors and lenses. Fiber optic lasers use a strand of glass fiber to amplify the light beam.

CNC laser cutting techniques include:

- Fusion cutting. The area on the material to be cut is heated to a molten state, then a pressurized stream of inert gas (such as nitrogen or argon) is blown through the kerf (cutting area), creating the cut. Fusion cutting is most often used for high alloys of steel and aluminum, in thicknesses up to 15mm.

- Flame cutting. Flame cutting uses the laser’s heat to trigger the oxidation process between an assist gas, such as oxygen and the metal. The resulting flame is used to create precision cuts in the metal workpiece. This method is most frequently used on low-alloy steels with thicknesses up to 25mm.

- Sublimation cutting. Also called vaporization or remote cutting, a laser is used to heat the material until it evaporates or vaporizes in specific places without the need for a support gas. This method is primarily used for cutting thin sheets.

The industrial laser cutting process is fairly straightforward and produces clean, accurate, complex parts with minimal finishing required. While there may be variables for specific projects, the general process for laser cutting will look something like this:

- Design and development. After initial conception and development, designers must create a computer-aided design (CAD) file for the product they wish to fabricate. This CAD file is then converted to a computer-aided manufacturing (CAM) file, which can be read by the CNC laser cutter as instructions.

- Material selection. Laser cutting is compatible with nearly all metals, including aluminum, copper, steel, and tungsten. The most appropriate cutting method will depend heavily on the selected material.

- Tool selection. The appropriate laser cutting tool is selected based on the design specifications and the material selection. Fiber optic lasers can be better for thinner pieces or more reflective materials. CO2 lasers can be best for thicker, harder, denser materials.

- Machine configuration. The laser cutting machine must be configured for the design and material. Power levels and laser beam pulse frequency must be set appropriately for the thickness and type of material.

- Cutting. The material gets loaded into the machine, and the computer-guided laser cuts the workpiece as instructed by the design.

Advantages of Laser Cut Parts

CNC laser cutting services offer many advantages over other fabrication techniques, including:

- Greater precision with cleaner edges

- Cost savings over plasma cutting

- Rapid turnaround and shorter lead times

- Increased versatility

- Reduced material waste

While laser cutting has become popular for many material types, including wood, plastic, and more, it’s extremely useful for cutting nearly all types of metal:

- Aluminum. The high strength-to-weight ratio of aluminum makes it a popular choice for laser-cut parts used in construction, aerospace, and transportation. Since aluminum is highly reflective, laser cutting aluminum usually requires a special system set up with a fiber optic laser to keep the molten aluminum from reflecting the laser beam back into the machine and damaging the cutting equipment.

- Stainless steel. Strong and corrosion-resistant, stainless steel one of the most common materials used in laser cutting operations. Stainless steel is typically cut using CO2 laser cutters with a fusion cutting technique.

- Steel. Affordable, ductile, and versatile, mild or low-carbon steel sheets are easily is cut with a CO2 laser to form an expansive range of parts across industries.

Custom Laser Cutting Services from Metal Works of High Point

With 3-axis laser cutting systems, automated sheet loading and unloading, and a system enabling 24-hour operations, Metal Works of High Point can handle all your custom metal laser cutting needs. Our additional capabilities include welding, CNC forming, and CNC machining services in our state-of-the-art facility. With decades of experience, a record of superior customer satisfaction, and a commitment to quality and innovation, we stand ready to serve your fabrication needs.

Please contact us for more information or request a quote for our expert metal laser cutting services.